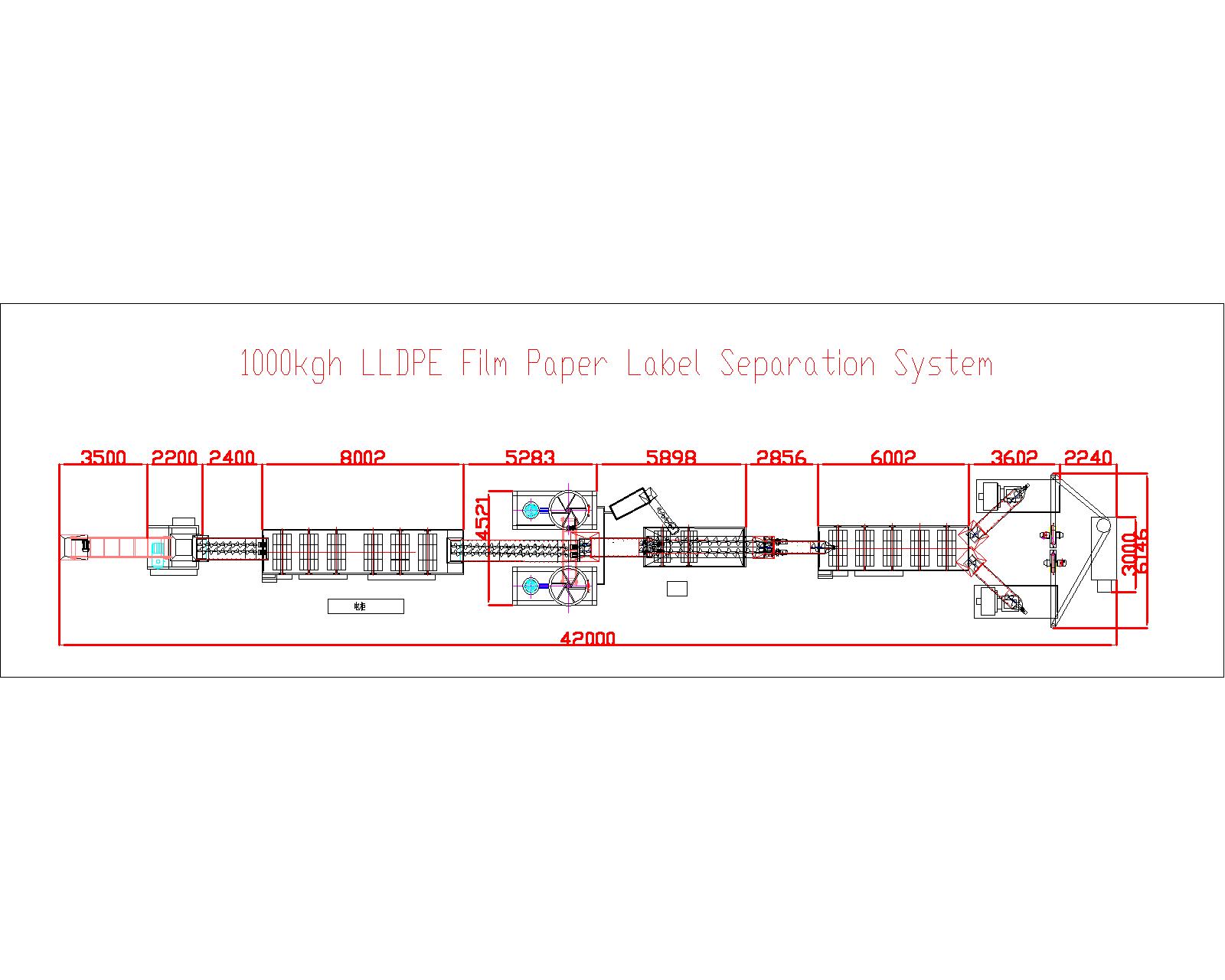

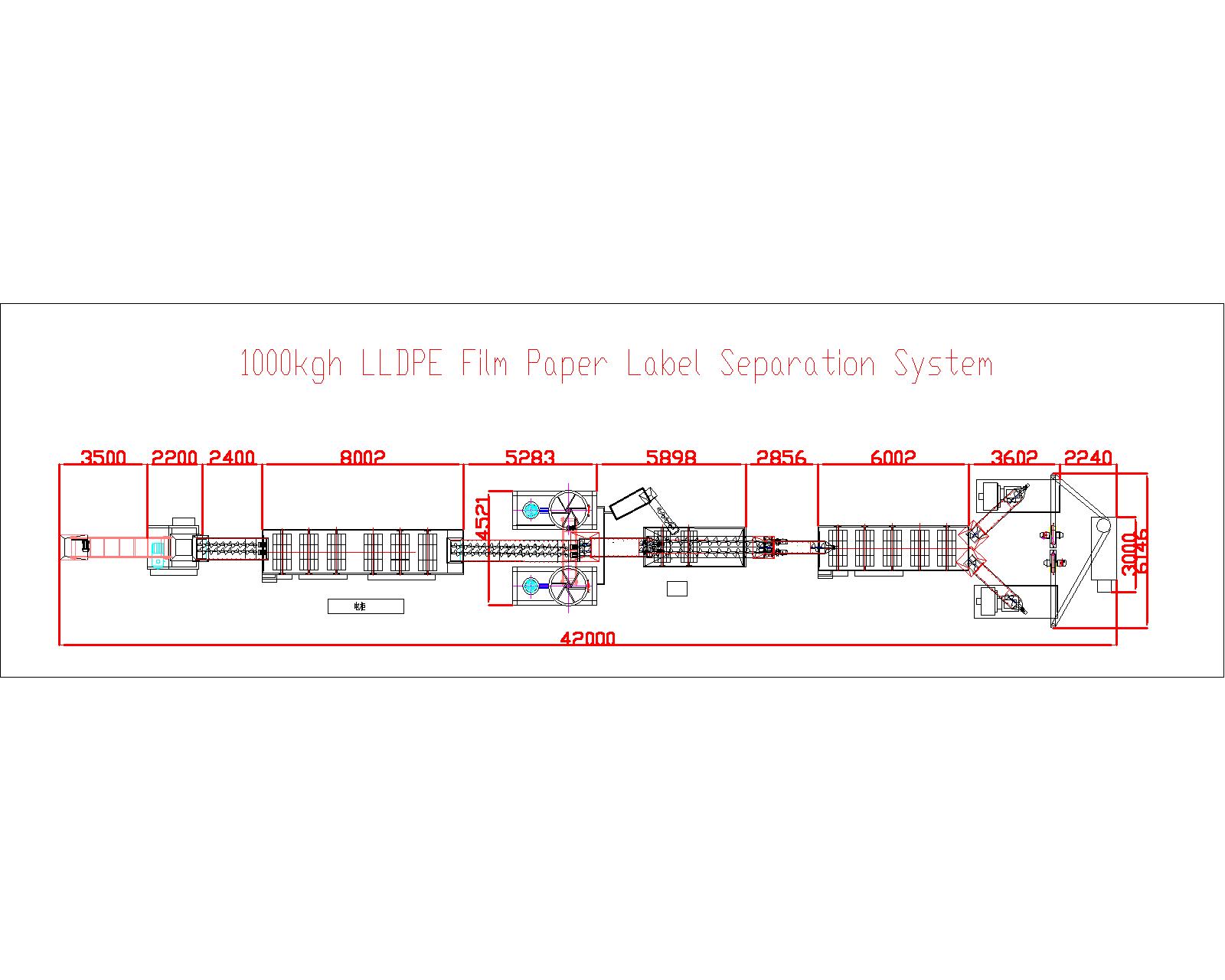

Post-consumer Waste Plastic LDPE LLDPE HDPE PP Film Bag Crushing Washing Squeezing Drying Machine Film Paper Tag Separation Line

Introduction:

Post-consumer PP PE film/bag washing recycling line is mainly used to clean the waste PE/LDPE/LLDPE soft films and PP woven/jumbo/ton bags. It is mainly consist of 3 parts as following:

1) Film Shredding/crushing system.

2) Film Friction washing/floating washing system.

3) Film Squeezing drying system.

By the high efficiency washing units, the final film flakes will be clean and dry.

The moisture will be strictly controlled within 3%-5%.

Application:

Material | LDPE,LLDPE,PP,HDPE,PET,ABS,PC etc |

Shape | Film,Woven Bag,Bottle,Lumps,Pipe etc |

Type | Baled,Loose,Scrap,Roll |

Capacity | 300kg/h,500kg/h,800kg/h,1000kg/h,1500kg/h,2000kg/h |

PP PE film recycling machine working flow chart:

&Crushing:

The shredder/crusher will firstly cut the film, the film after cutting will be in size of 40-60mm. It is small and easy to wash.

&Washing:

By friction washer in front of floating washing tank,it is to remove the mostly of sand,soil,etc which can maximum reduce the dirt into floating tank.

The deep film washing tank with moving rollers can fully wash the film slowly. The dirt will fall down,washed film will be float and send to next.

Sometimes,the LDPE/LLDPE may stick with some paper/label,price tag. It need force washing separation. It is named paper/plastic separation removing system.

&Drying:

Squeezing machine with heat will remove water very easily. The final granules shape film can be ensure 3% moisture.

Basic data of RETECH PE film washing line:

Model | Power | Water Consumption | Capacity |

RM300 | 80kw/h | 4-6 ton/h | 300kg/h |

RM500 | 150kw/h | 6-8 ton/h | 500kg/h |

RM1000 | 225kw/h | 8-10 ton/h | 1000kg/h |

PE/LDPE/LLDPE Film Crusher:

Name | Technical Parameters |

Motor Power | 37kw,55kw,90kw,132kw |

Rotor Size | 560*800mm,620*1000mm,760*1400mm |

Moving Blades | 10PCS,14PCS |

Fixed Blades | 4PCS |

Material of Blades | D2,SKD-11 |

Screen Hole | 80mm,100mm,120mm |

Capacity | 300kg/h,500kg/h,1000kg/h |

Function | To cut the big plastic into small flakes. |

PE Film Friction Washing:

Name | Technical Parameters |

Motor Power | 5.5kw,11kw,15kw,22kw |

Screw Diameter | 380mm,420mm,500mm |

Thickness Blades | 5mm |

Length | 3200mm,3800mm,4500mm |

Material | Stainless steel 304 |

Screen Hole | 3mm |

Capacity | 300kg/h,500kg/h,1000kg/h |

Function | To remove the soil and sand/stone,working with paper separation system will strongly remove label paper. |

PE Film Sinking -Floating Washing Tank:

Name | Technical Parameters |

Motor Power | 2.2kw*3 |

Length | 4500mm,6000mm,8000mm |

Width | 1320mm,1600mm,2000mm |

Material | Stainless steel 304 |

Capacity | 300kg/h,500kg/h,1000kg/h |

Function | To separate dirt and to clean film,working with chain conveyor will saving water consumption. |

PE Film Squeezing&Drying Machine:

Name | Technical Parameters |

Motor Power | 90kw,110kw,132kw,160kw |

Gearbox | 315,330 |

Screw Diameter | 300mm,320mm,350mm |

Material | 38CrMoA1A |

Capacity | 300kg/h,500kg/h,800kg/h |

Function | To dry and compact the LDPE film |

FEATURES of OUR LDPE/LLDPE film Washing Line:

1) Latest structure of crusher, ensure maximum to get 3000kg/h for LDPE film.

2) High efficient label/paper removing system can completely separate paper tag and plastic film.

3) Multiple-Channels washing tank design,best washing effect.

4) Squeezer application on drying, ensure moisture 3%.

5) High output,2000kg/h-3000kg/h