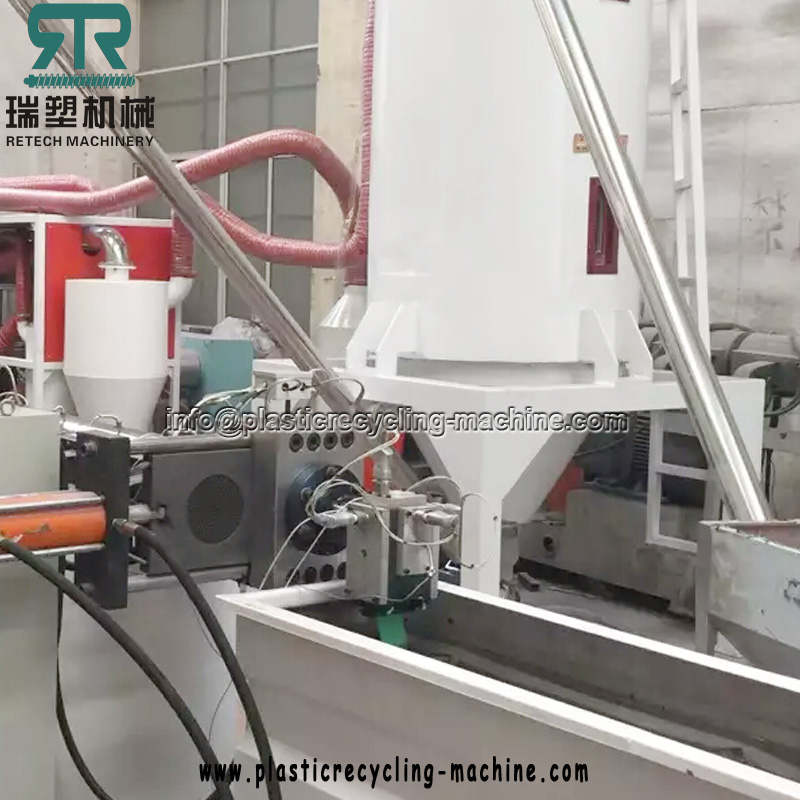

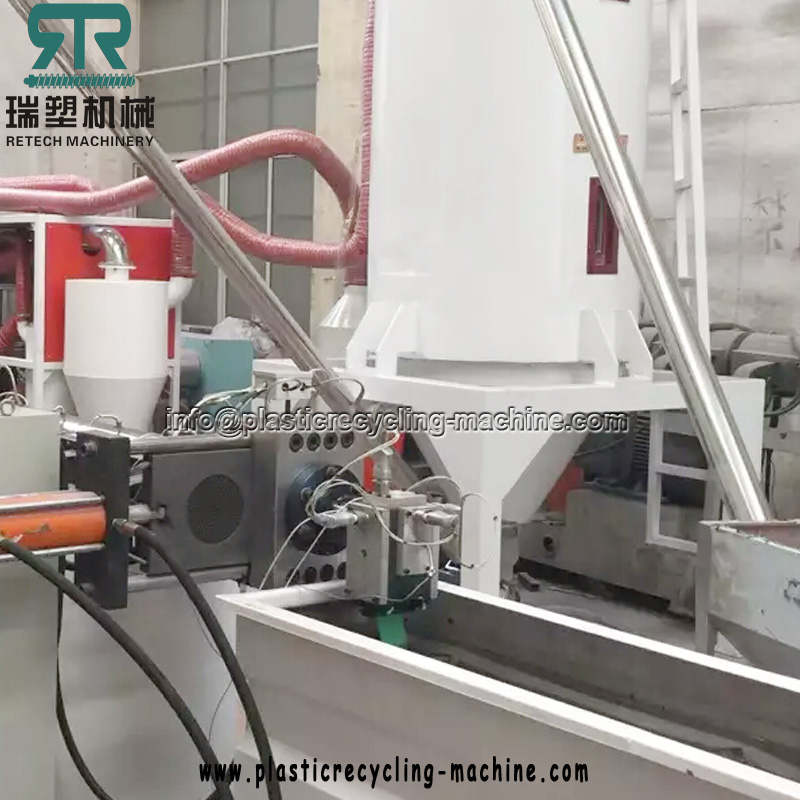

PET Strap Extrusion Production Line

Features of PET strap extrusion line

screw with compression ratio especially for PET, gradually changing diameter and deeper thread groove at the melting part; gearbox with hardened gears; die can be precisely adjusted to ensure stable production and smooth surface of straps; stainless steel cooling trough with four thermo treatment processes displaces the traditional one; haul off rollers with bigger size ensure the quality of products; new rolling technology overcomes the shortcomings of traditional rolling machine like high gradient and bending delectation; laser embossing roller makes clear and even patterns.

PET packing strap is widely used, replaced for steel strap for packing application internationally, because of its good tensile strength, flexible, low prolongation rate, good performance of high temperature resistant, non-rustiness, and low use-cost, etc, it is used in steel, construction material, chemical fiber, paper making, tobacco, agriculture, election, etc.

Characters of PET strap extrusion line

Adopts advanced dehumidify dryer system. It makes sure the material humidity at 80PPM at 50PPM dew point. Meanwhile, it compact material and increase the viscidity.

Adopts closed cycle transport system after dryer to avoid contact with outside air and make sure the material drying continuously.

Extruder adopts special screw for PET. The screw has unique separate and mix property to make sure uniform plasticizing. The screw is suitable for recycled PET bottle flakes, PET mixture and original PET material. And the extruder adopts ration forced feeding to make sure the stable extruding. It makes sure the product uniform.

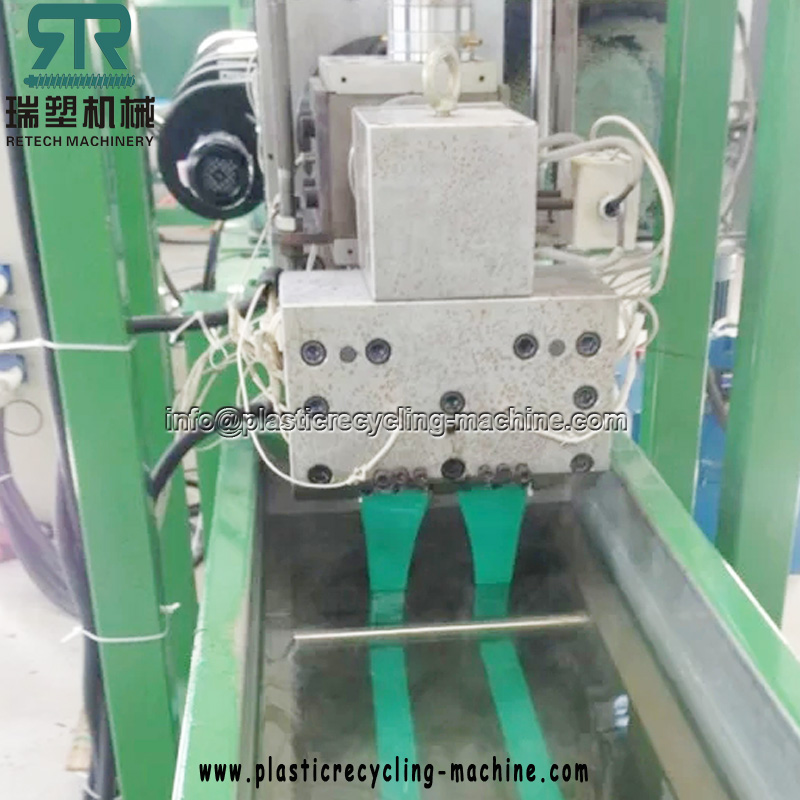

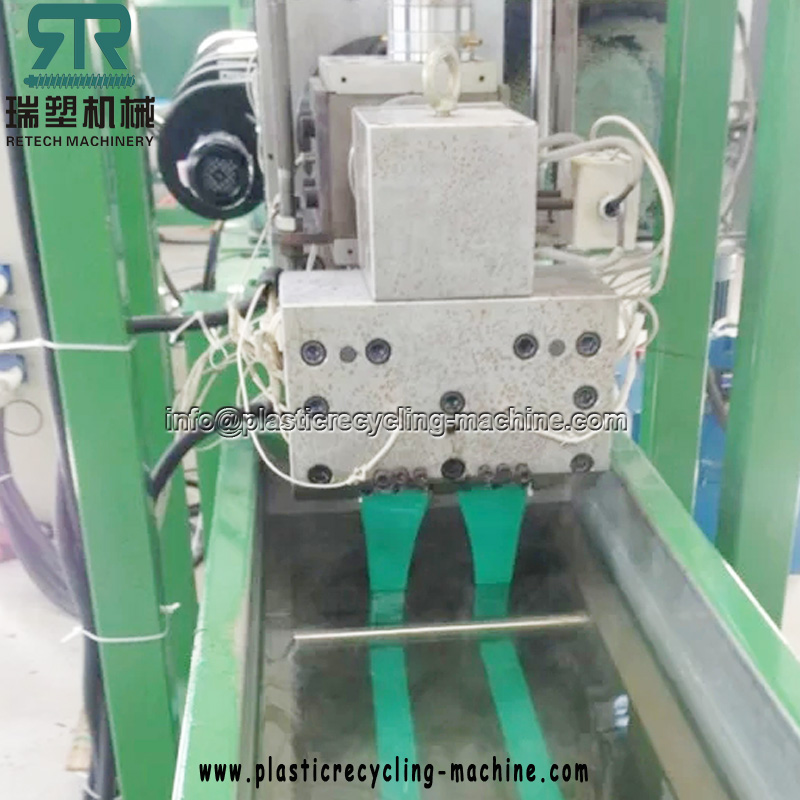

Produce different model product at one die and mould, adopting hydraulic screen exchanger without material leak.

Static cooling roller replaces the water cooling tank. The roller will cool the strap at the constant temperature. It improves the product's stretch intensity.

The strap after formed will be warm and anneal treated to wipe off the part stress remained after stretch. It makes molecule tropism be steady to avoid strap distortion caused by storage.

The winder adopts double work position and auto-meter. It is easy operation and convenient coil change.

Centralized electrical control, PLC self-correcting control make it is easy operate.

Advantages of our PET strap extrusion line

1. The raw material treatment is by our dehumidify and dryness system, it ensures the humidity in raw material less than 80PPM.

2. Closed circulation feeding system prevents the material from exposure on air to keep the dryness of raw material.

3. The screw is specially designed for PET application, it consists of separate and mixing part to keep the even plasticizing, also by fixed material feeding system, the extrusion is stable, which ensures the good dimension of PET strap.

4. The machine can produce 1/2/4 strap at the same time.

5. The mould is specially designed, equipped with two-stage filter.

6. Constant temperature heating device provide even cooling environment for PET strap to raise the tensile strength performance.

7. Anneal treatment for finished PET strap to remove the part remaining stress to keep good shape

8. The winder is double disk type with easy operation and coil changing.

Models of PET strap extrusion line

Model | Capacity | Working Power | Width Range | Thickness Range |

RPSJ75 | about 2.5Ton/day | 50~55kw/h | 12~20mm | 0.6~1.2mm |

RPSJ90 | about 4.5Ton/day | 110~120kw/h | 12~20mm | 0.6~1.2mm |

RPSJ120 | about 8.5Ton/day | 180~200kg/h | 12~20mm | 0.6~1.2mm |