Sedimentation type Waste water treatment plant for dirty water from Plastic washing recycling line

Application:

The waste water from plastic film/bottles/bags washing recycling line, which contains much sludge, sand dirties.

Aim:

Treating the dirty water is to be reusing or discharging standard.

Advantages:

1. Could design and adjust the structure of treatment machines according to the waste water real condition.

2. The whole process runs continually, no retention batch time.

3. All machines runs fully automatically completely.

4. Only need chemical to help processing the water, no need biochemical process. It could save much time and machines covering space.

5. No need full time worker, only part time worker is enough for guaranteeing the whole plant normal running.

6. Very low power consumption, very low maintenance cost and very long life running.

7. Big Water processing capacity from 5~120Ton/h

Brief Introduction:

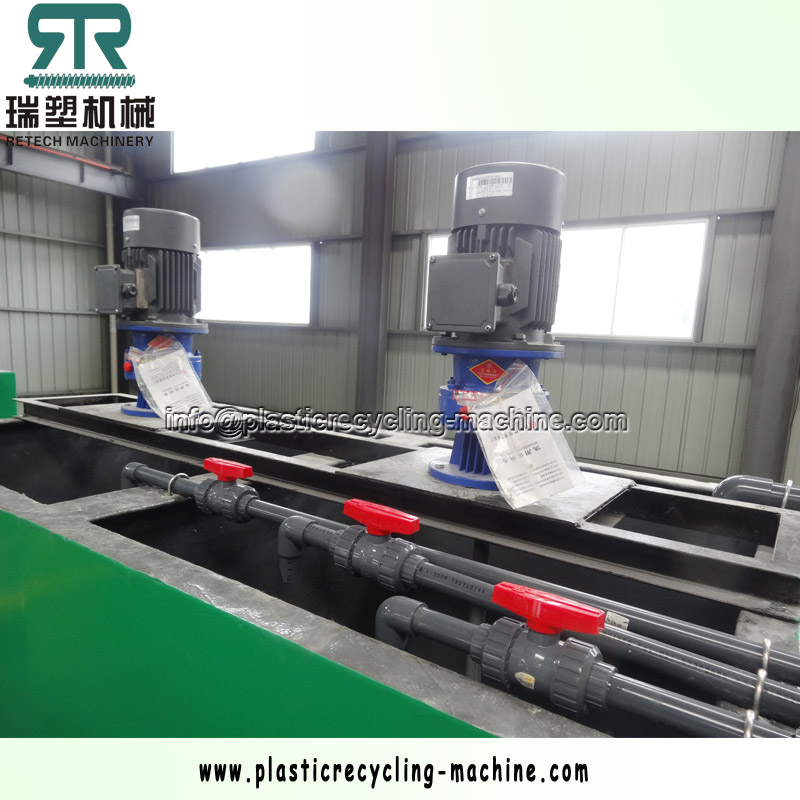

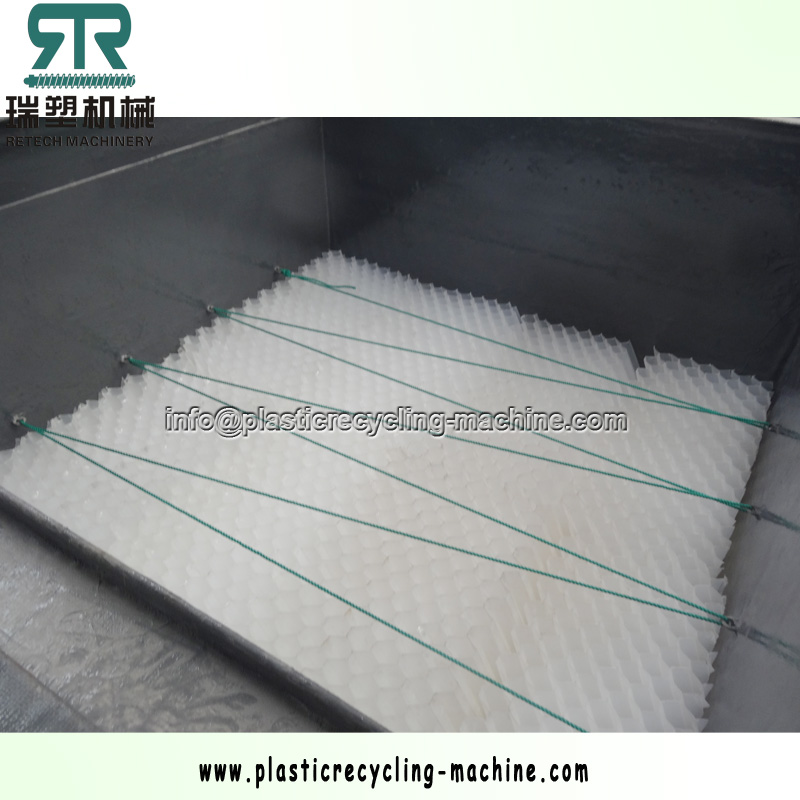

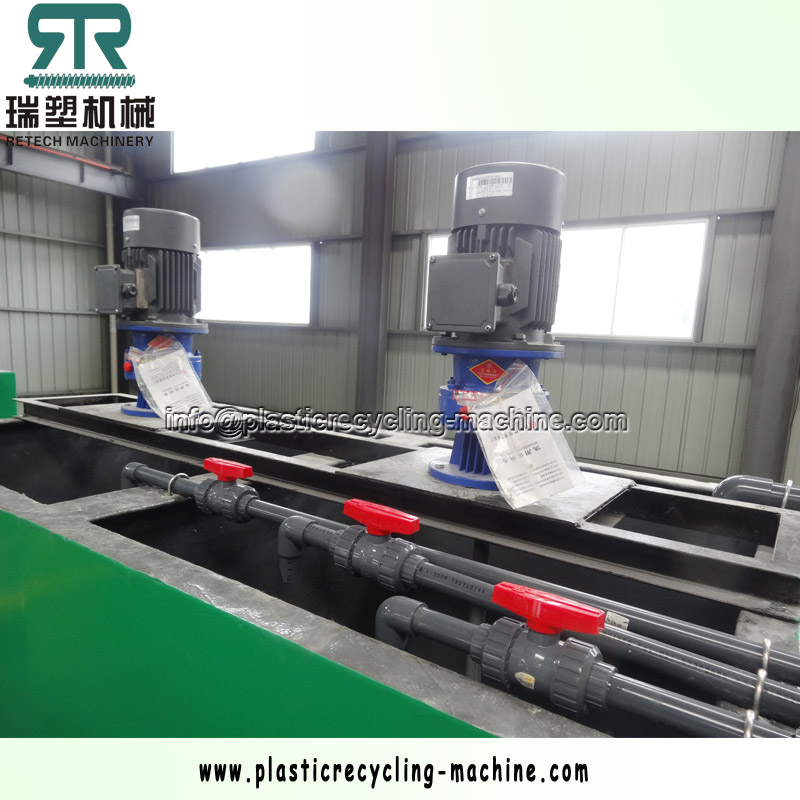

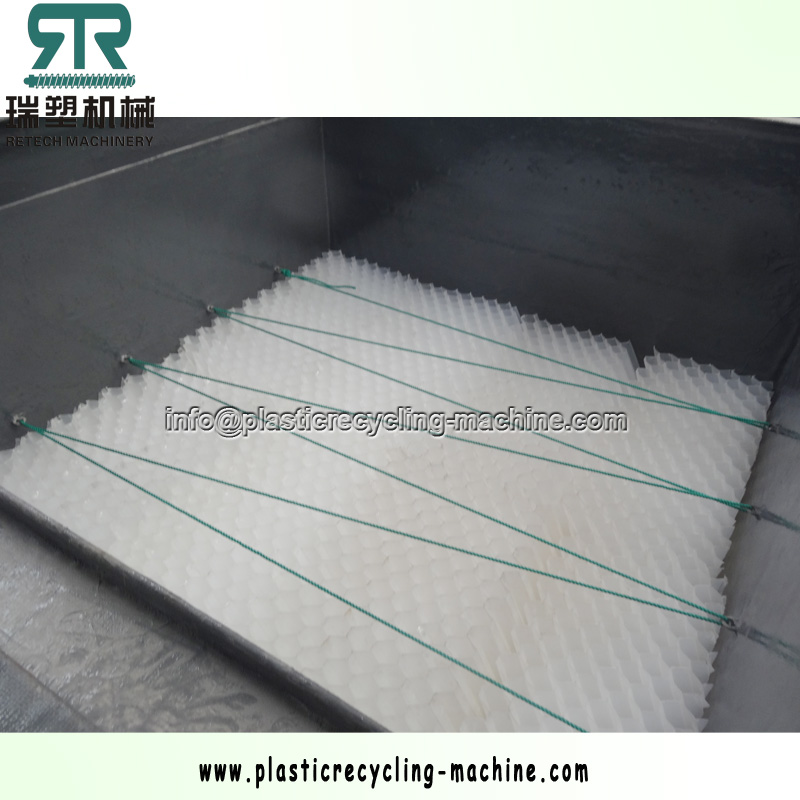

The waste water from plastic washing line goes into the waste water tank for storage. The waste water in the waste water tank will be pumped into reacting tank. When the waste water is in the reacting tank, the chemicals will be added into the tank. The main chemicals are acid (controlled by PH meter), flocculants, and coagulant. Due to the situation of the raw water, we design to stay the raw water in the reacting tank for 15 minutes, which can ensure the water and chemical reacting enough to form the coagulations separating from the water and also avoiding too much chemicals added, high running cost maladies. There are installed over pass, stirring machine, which also ensure the reacting fully to form particle coagulations. The particle coagulations will absorb some other impurities, then the particles will become bigger and bigger. In order to enhance the coagulating effect, it also needs to add some coagulant aids PAM (its chemical name is polyacrylamide). Then next the coagulations and water will go into the sedimentation tank together. By the inclined tubes in the sedimentation tank, the coagulations will be separated send settle down to the bottom of tank and form to be sludge. Then it realizes micro coagulations separating out from the water.

By sedimentation, the water becomes clarified and over flow into the clean water tank. There is installed a liquid level controller. When the water level goes up to the max, the filtering recoil pump will start to work and pump the water into the sand filter tower. The main function of the sand tower is to remove the suspended solid left in the clean water. After the sand filter tower is active carbon filter tower. Usually after the active carbon filter, the water can achieve discharging standard or reusing standard.