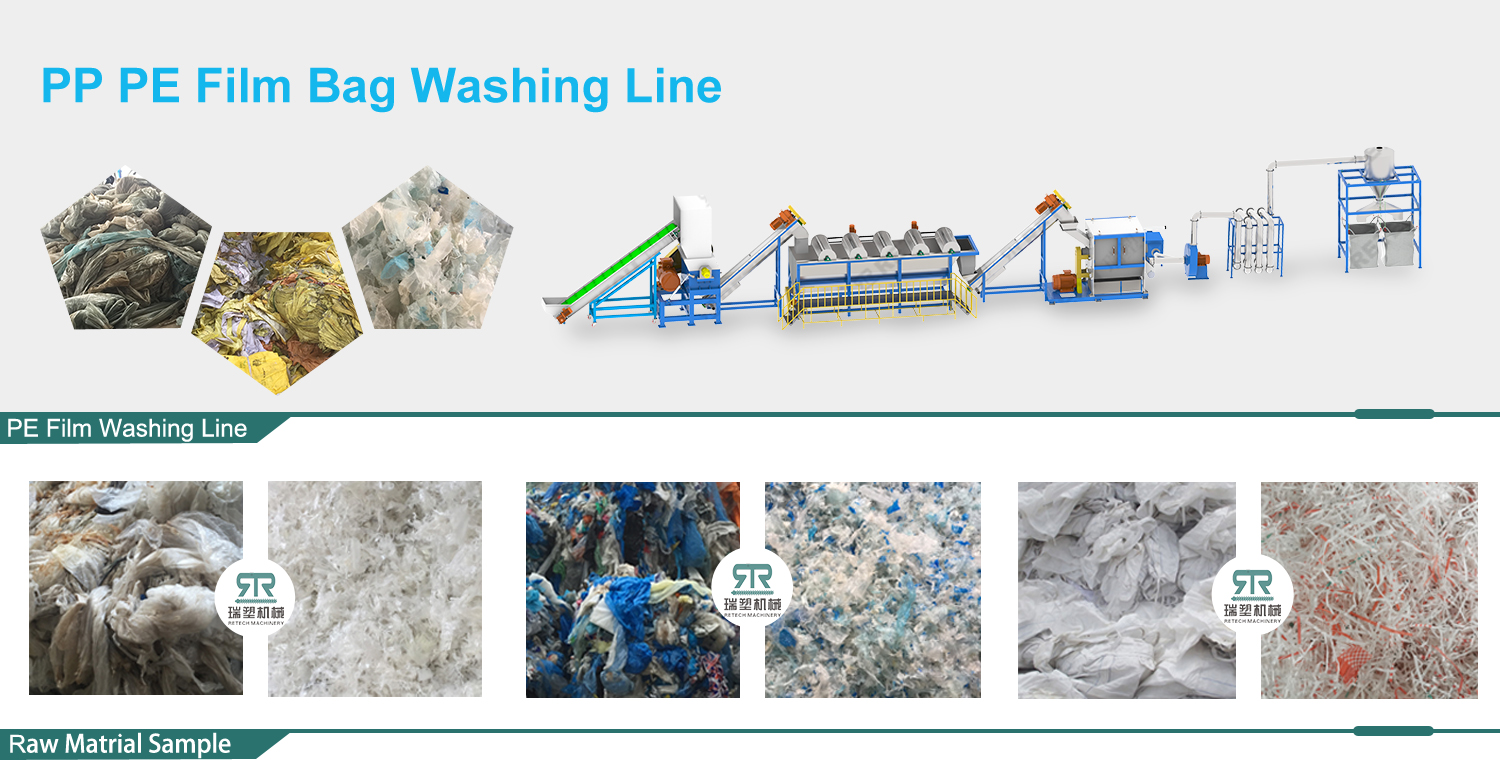

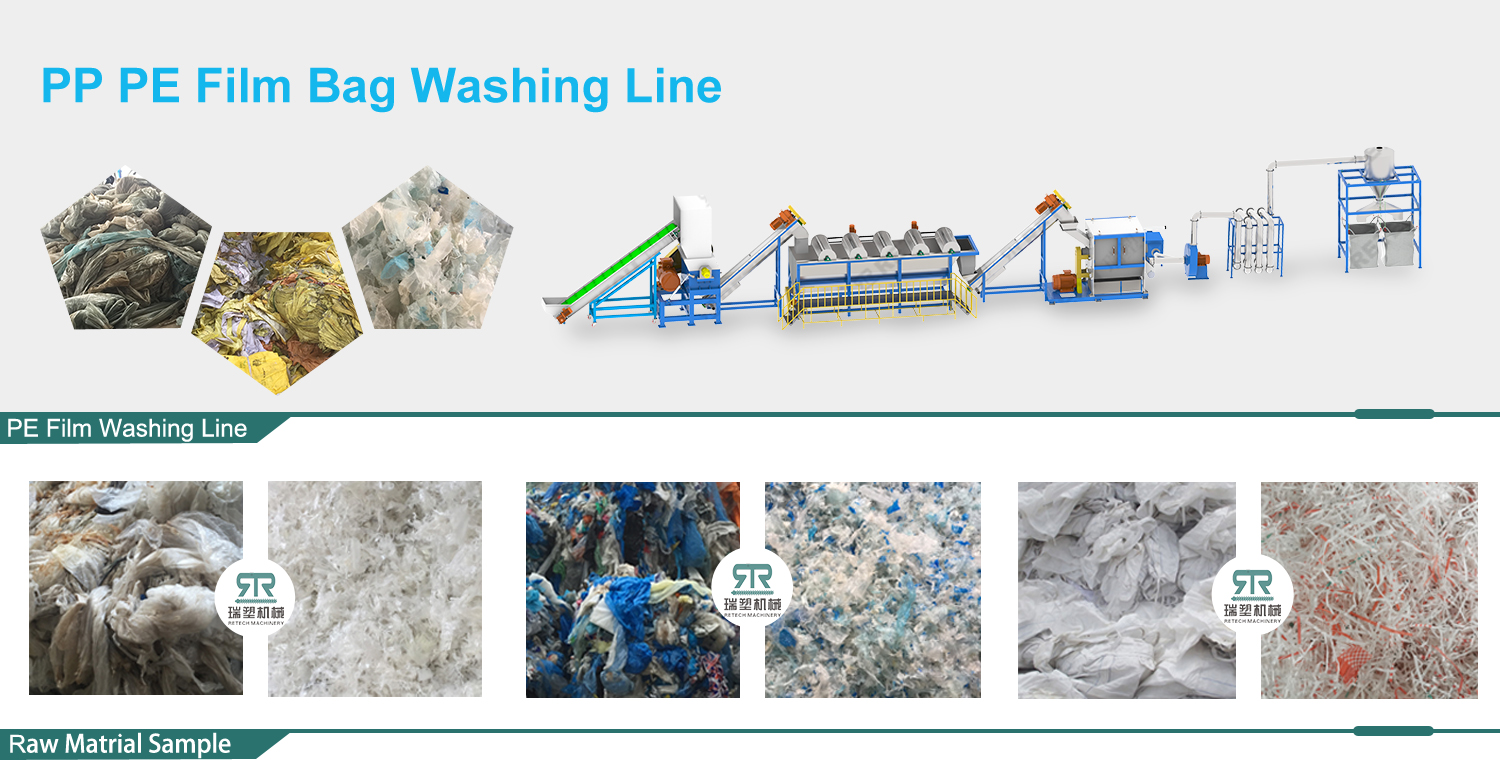

1000kg/h PE/PP/LDPE/LLDPE film woven bag completely washing recycling extruder pelletizing line

Applications:

LDPE agriculture film washing recycling line

LLDPE stretch wrapping film washing line

PP woven bag washing recycling plant

PP jumbo bag washing line

Photos of our 1000kg/hr PE film washing line:

Equipment List to our plastic film washing line:

No | Equipment name | Quantity | Power |

1 | Belt conveyor | 1 | 3kw |

2 | Single shaft shredder | 1 | 90kw |

3 | Belt conveyor | 1 | 2.2kw*2 |

4 | RSPC1200-Wet Crusher | 1 | 90kw*2 |

5 | Double screw conveyor | 1 | 3kw*2 |

6 | High speed friction washer | 1 | 55kw |

7 | Double screw conveyor | 1 | 3kw*2 |

8 | Film floating washer | 1 | 2.2kw*3 |

9 | Double screw conveyor | 1 | 3kw*2 |

10 | High speed friction washer | 1 | 55kw |

11 | Double screw conveyor | 1 | 3kw*2 |

12 | Dewatering machine | 1 | 132kw |

13 | Drying system1 | 1 | 48kw+11kw |

14 | Transition hopper | 1 |

|

15 | Drying system2 | 1 | 36kw+11kw |

16 | Storage hopper | 1 | 2.2kw*2 |

17 | Electrics | 1 |

|

Remark: After crushing,washing,squeezing drying processing steps,the final humidity will be within 5%, it is easy to make granules by our compactor pelletizing machine.

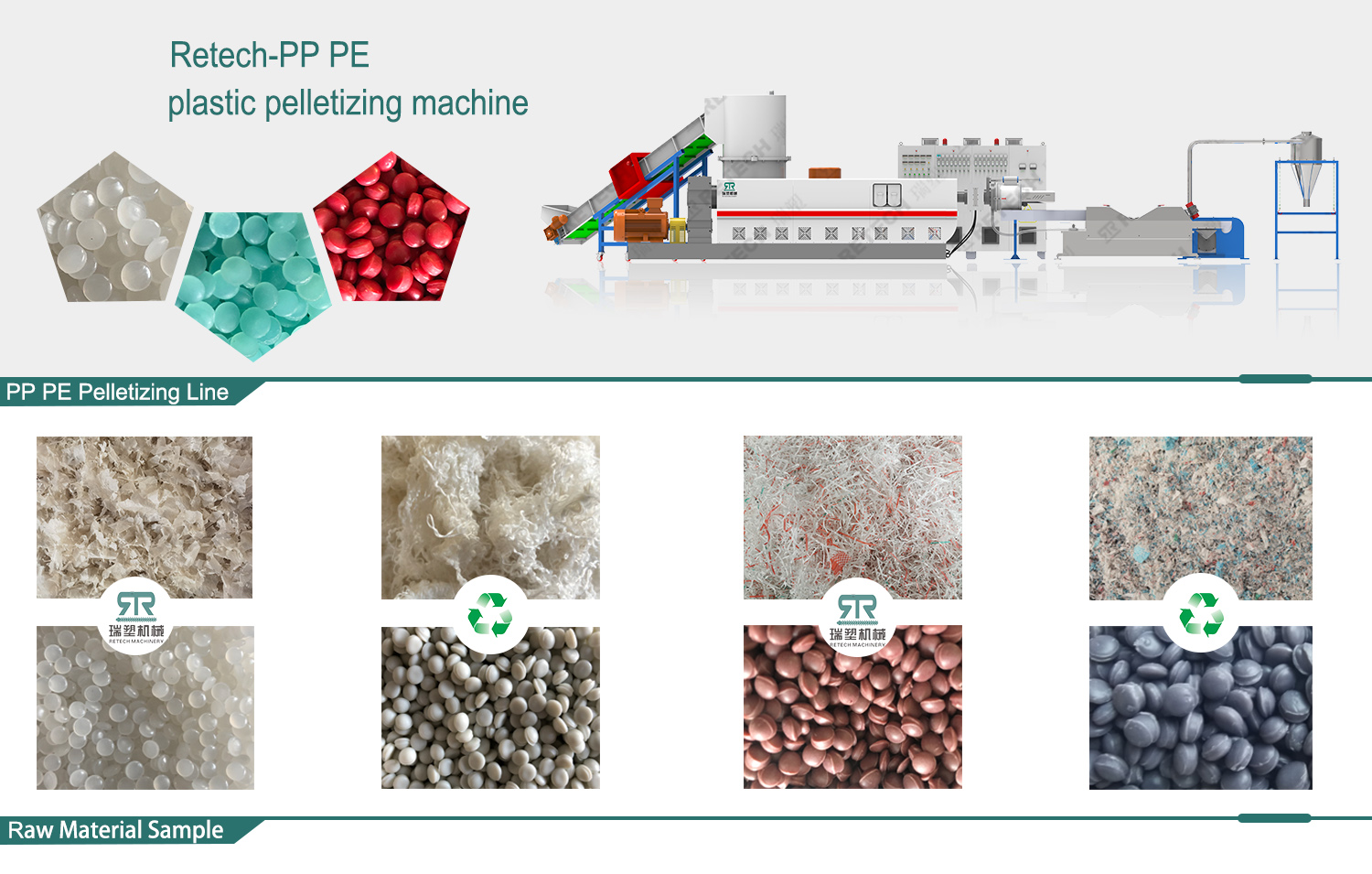

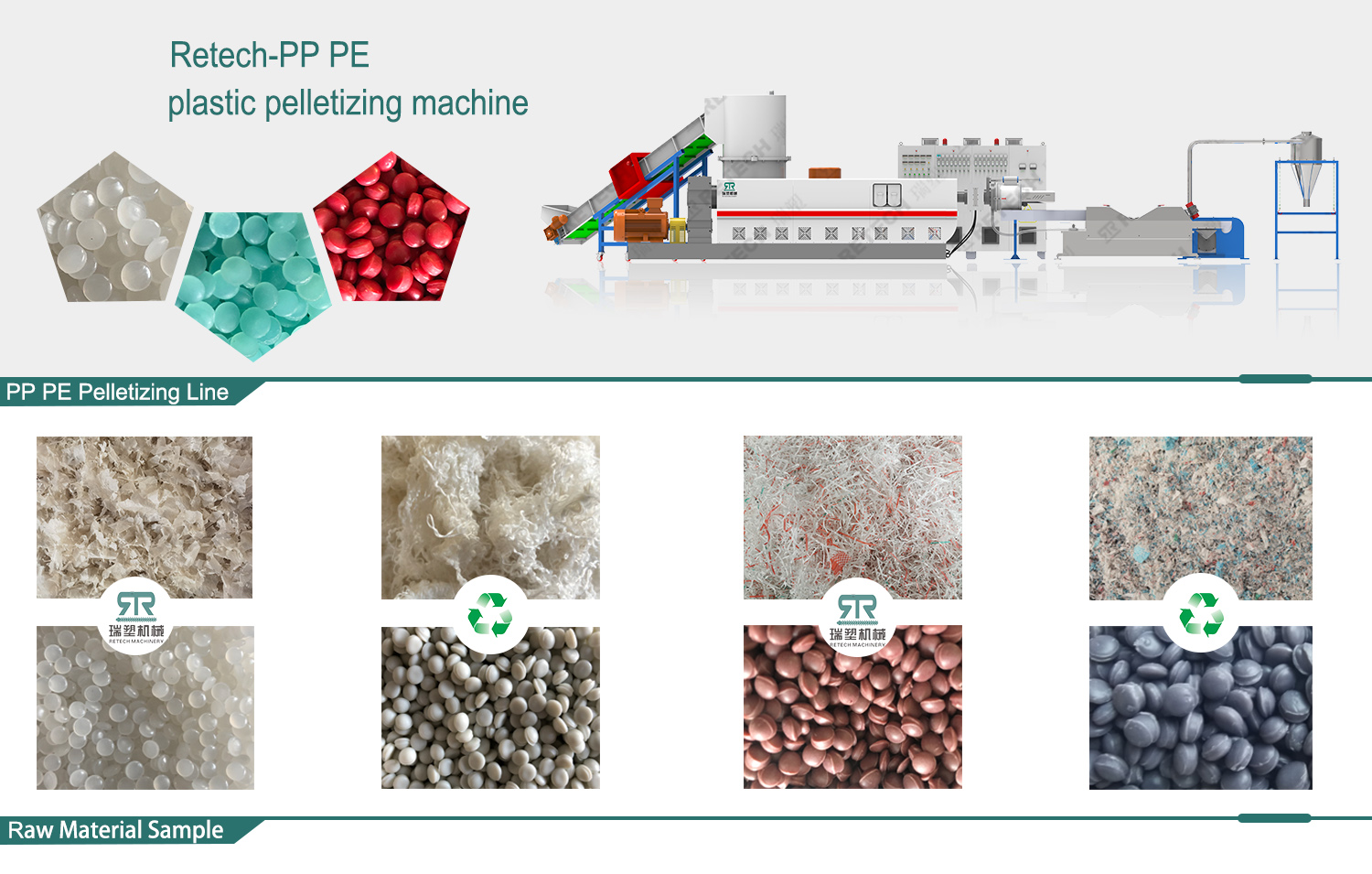

RCSJ Series Plastic Compactor PP PE Film Pelletizing Line

Applications:

LDPE agriculture film pelletizing line

LLDPE stretch wrapping film washing pelletizing line

PP woven bag washing recycling plant

PP jumbo bag washing granulating line

Equipment List:

No. | Name | Quantity |

1 | Belt conveyor with metal detector | 1 |

2 | Compactor | 1 |

3 | RCSJ180/28 main extruder | 1 |

4 | RCSJ200/12 main extruder | 1 |

5 | Hydrualic screen exchanger | 1 |

6 | Die face cutting system | 1 |

7 | Water flume | 1 |

8 | Dewatering machine | 1 |

9 | Vibrating screen | 1 |

10 | Blower conveying system | 1 |

11 | Storage hopper | 1 |

12 | Electric panel | 1 |