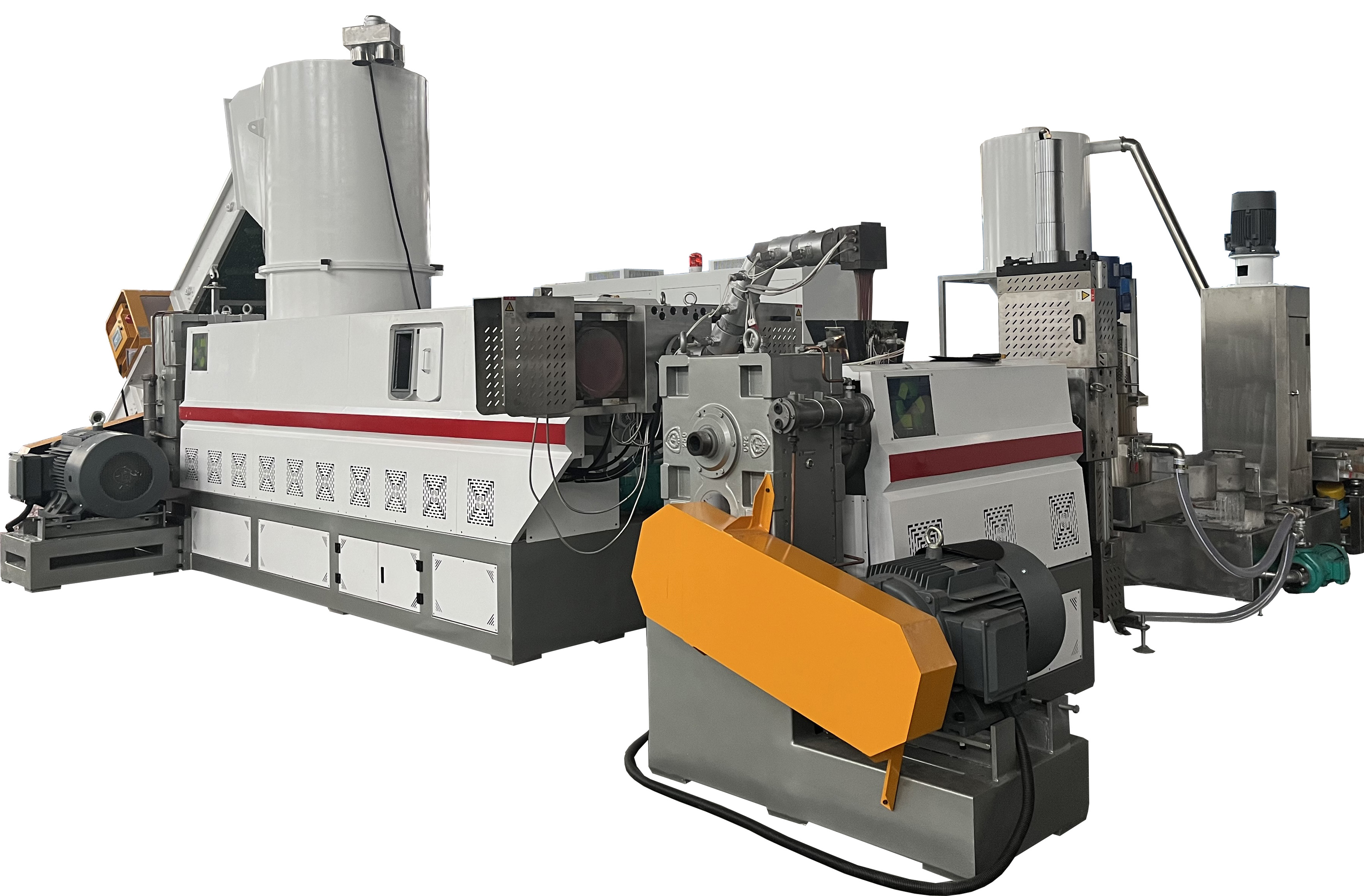

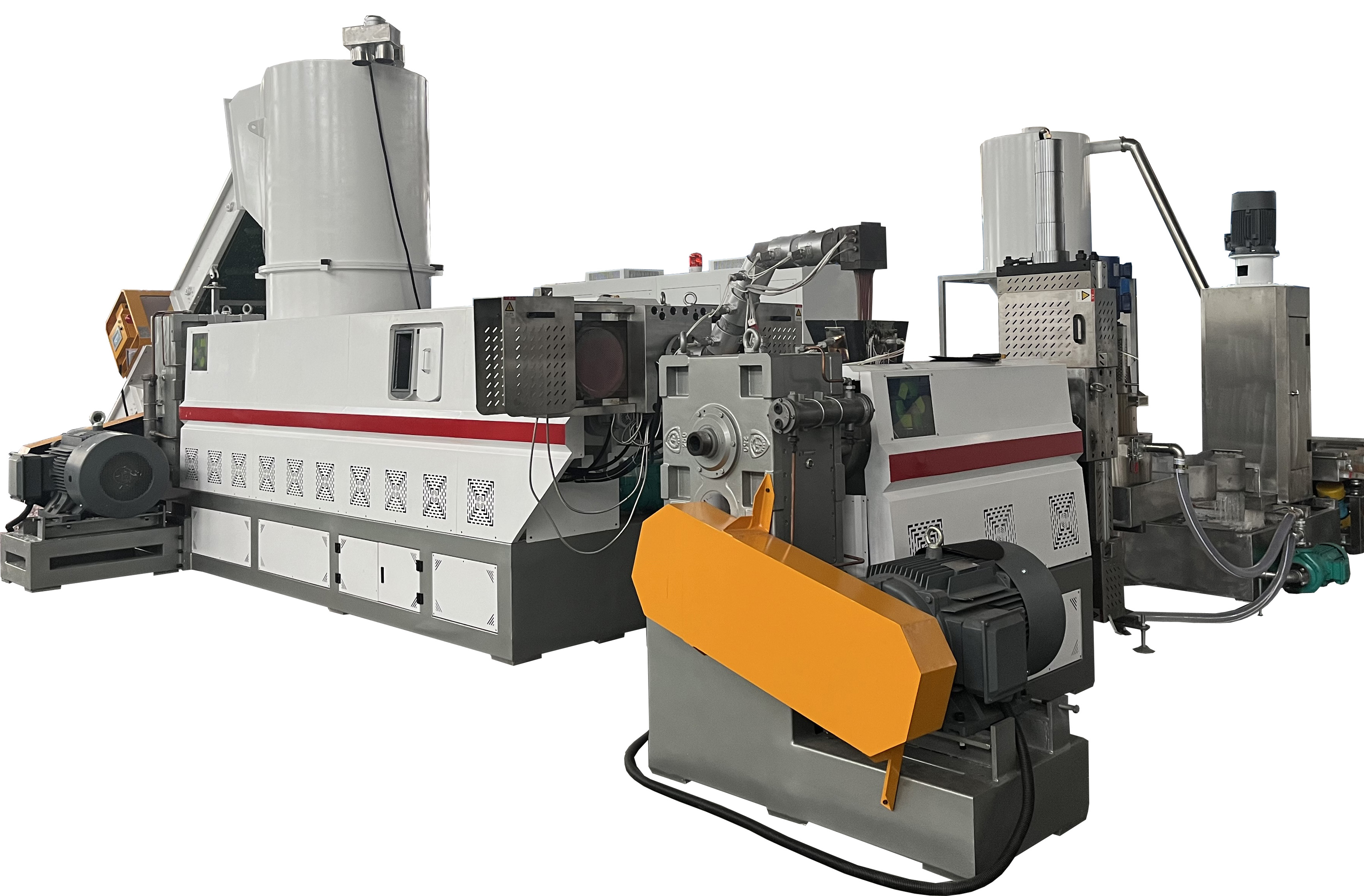

RCSJ180-200 PP PE Film Bag Compactor Pelletizing Line

Applications:

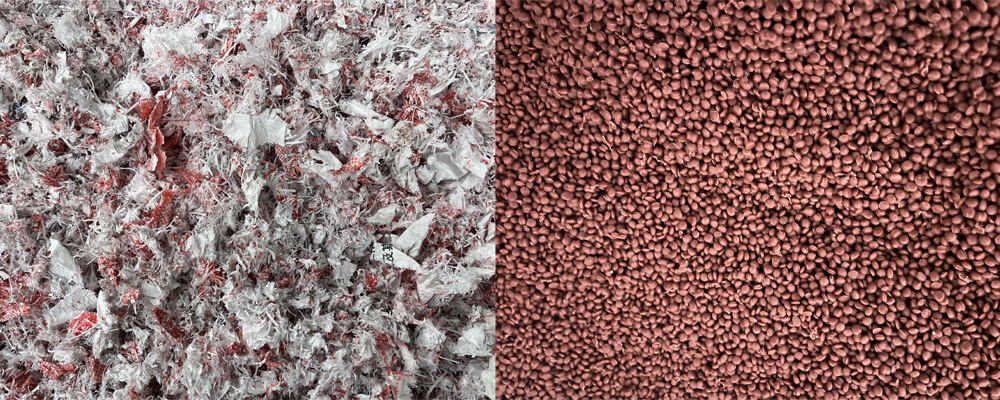

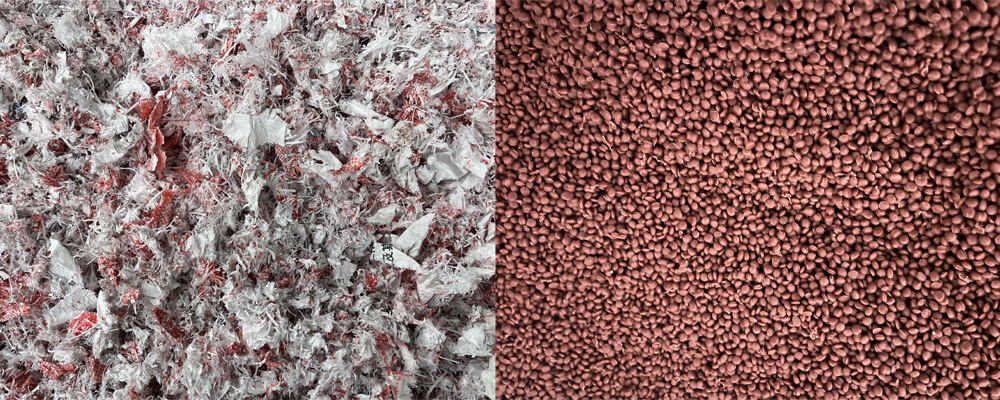

RCSJ series PE film PP woven bag recycling pelletizing machine is working for recycle waste plastics like LDPE film,HDPE bags,PP jumbo bag,PP woven bag,etc.

Technical Parameters:

| RCSJ series plastic PP PE film bag pelletizing line |

| Models | RCSJ | RCSJ85 | RCSJ100 | RCSJ130 | RCSJ160 | RCSJ180 |

Capacity

| (kg/h) | 150-220 | 260-320 | 450-550 | 650-850 | 900-1200 |

Energy

| (kw/kg)

| 0.2-0.33

| 0.2-0.33 | 0.2-0.33 | 0.2-0.33 | 0.2-0.33 |

| Compactor | kw | 37 | 55 | 75 | 110 | 132 |

| Extruder dia | mm/kw

| 85/55kw | 100/90kw | 130/132kw | 160/185kw | 180/250kw |

| Filter | type | 2 pistons | 2 plate | backflush

| self-cleaning

| laser filter |

Downstream

| type

| water ring | die face | strand | optional | optional |

Key units on plastic pelletizing machine:

1.Belt conveyor(with metal detector)

Belt conveyor+ metal detector is a group to send the material to compactor. Metal detector will find metals and warn operator to stop belt. They could protect the blades and screw.

2. Compactor

With optimal design of rotary blades and stationary blades.

The material got cutting, mixing and compacting in the compactor uniformly, to ensure the material heated and dried effectively which guarantee a fast and stable feeding from the compactor into the extruder.

3. Single screw extruder(with vacuun degassing)

Referring to the Germany design concept and method, designed for single screw extrusion machine, with the structure of involute gear teeth.

Force vacuum degassing system with two vents to get rid of the low molecular, moisture and printing ink effectively, make sure high quality output products.

4. Filter screen

Plate type, pistion type and automatic self-cleaning type filter, Different choice according to impurity contents in material and client's habit.

Plate type filter is cost-effective and easy to operate which mainly used for regular thermoplastic as usual

filtration solution.

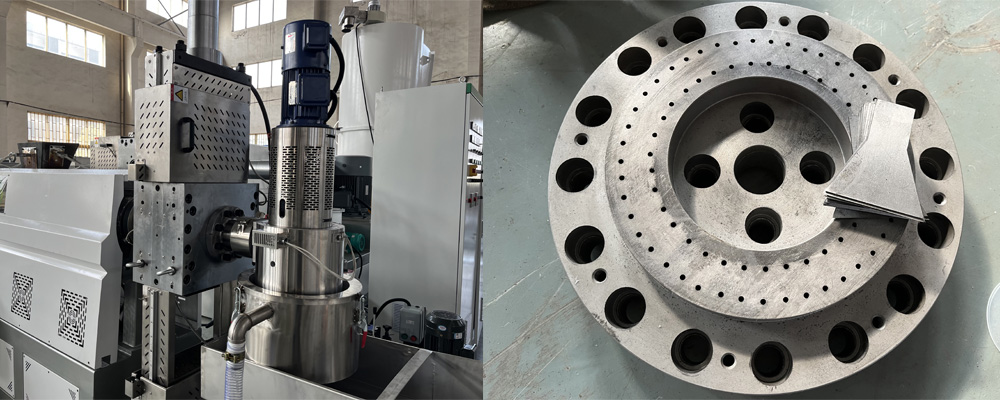

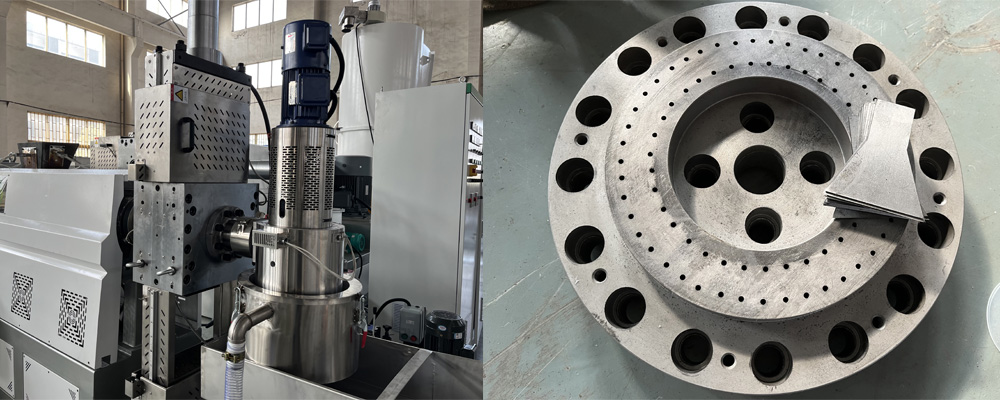

5. Water ring pelletizing unit

Cutting speed of pelletizer controlled automatically by PLC according to the pressure of die head, which could achieve the uniform size for output pellets.

Blades of pelletizer touch to die plate automatically by pneumatic system, make sure blades

contact with die plate properly, easy to operate and abrasion avoided.

6. Electric cabinet

All electrical units mounted in a strong safe electrical cabinet; >>Safety interlock principle applied in the system;

Inverter:ABB/FUJI/DELTA/TECO;

Contactor: Schneider;

Adopt CE safety electrical components;