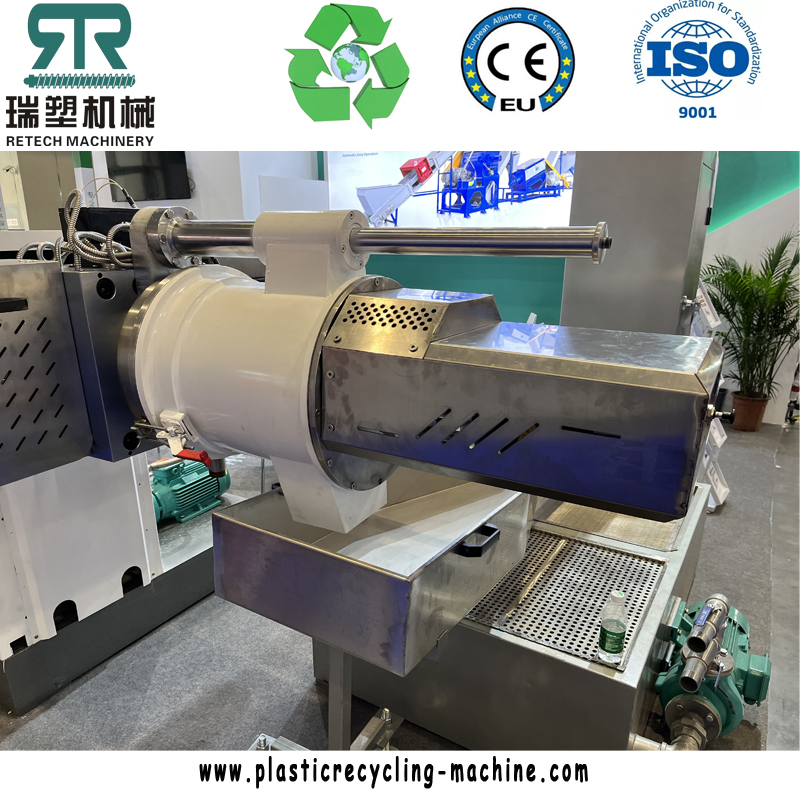

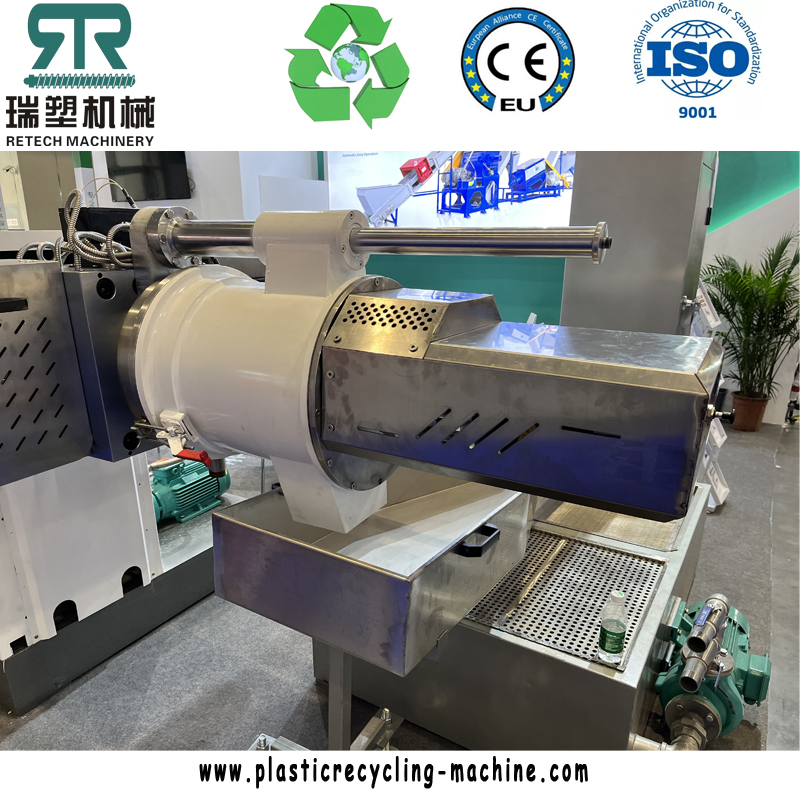

PP PE Plastic Laminated Multilayer Composite Film Recycling Pelletizing Granulating Line

Cutter compactor plastic recycling pelletizing line from Retech Machinery is designed for recycling plastic PP, PE, HDPE, LDPE, LLDPE, PA66, PC, PET, OPP, BOPET, ABS and etc. It is widely used in making bags, film rollers, stretch film, shrink film, muti-layer film, T-shirt bag cut-offs; foamed PE, sheet, food container, fruit net, cover, fiber, raffia, silk, yarn, woven bag, jumbo bag. Our cutter compactor recycling pelletizing machine can produce more than 10 kinds of plastic material.

Applications:

Models/Technical Parameters:

| Models | RCSJ85/100 | RCSJ100/120 | RCSJ130/150 | RCSJ160/180 | RCSJ180/200 |

| Screw diameter | 85mm | 100mm | 130mm | 160mm | 180mm |

| L/D | 33:1 | 33:1 | 33:1 | 30:1 | 28:1 |

| Compactor | 37kw | 55kw | 75kw | 90kw | 132kw |

Extruder

| 55kw | 90kw | 132kw | 185kw | 250kw |

| Output(kg/hr) | 200kg/hr | 320kg/hr | 500kg/hr | 750kg/hr | 1000kg/hr |

(Note: optional for single stage or double stage,optional for self-cleaning filter or plate filter)

1. Belt Conveyor

Feeding speed of conveyor belt or roll hauling off is fully automatic based on how full the compactor's room is. Metal detector can be combined with belt conveyor, and can interlock with contrl system, to warn and stop the system, in case that metal is found in feeding.

2.Compactor / Agglomerator

The rotatory blades in compactor will cut up the feeding scraps. Frictional heating which caused by high speed rotation blades will heat and shrinking agglomerating materials. Optimal designed guide structure compacts the material and directs it into extruder screw. Crushes, dries and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder.

3.Extruder

Single screw extruder applied to melting the material. The plastic scraps will be well melted, plasticized in a 33D processing section. With double-zone vacuum degassing system, volatiles such as low molecular and moisture will be removed efficiency, especially suitable to heavy printed film and material with water content.

4.Water-ring&Die-face cutting system:

Water-ring or die-face/Strand cutting ways are optionally adopted. In water-ring die-face cutting system, the rotary cutting blades will be pneumatically fit completely and closely to the die-face surface to ensure efficient cutting. Rotary speed of the blades is automatically adjusted by module system according to melt pressure at the die face.