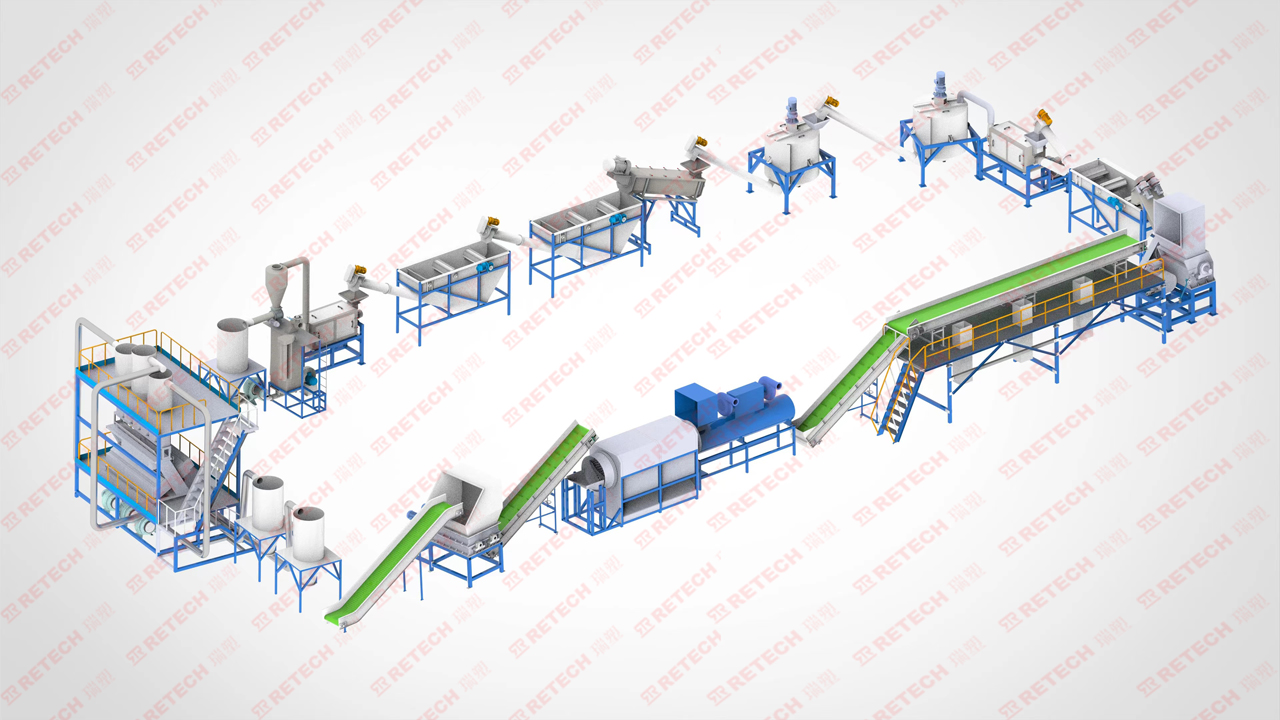

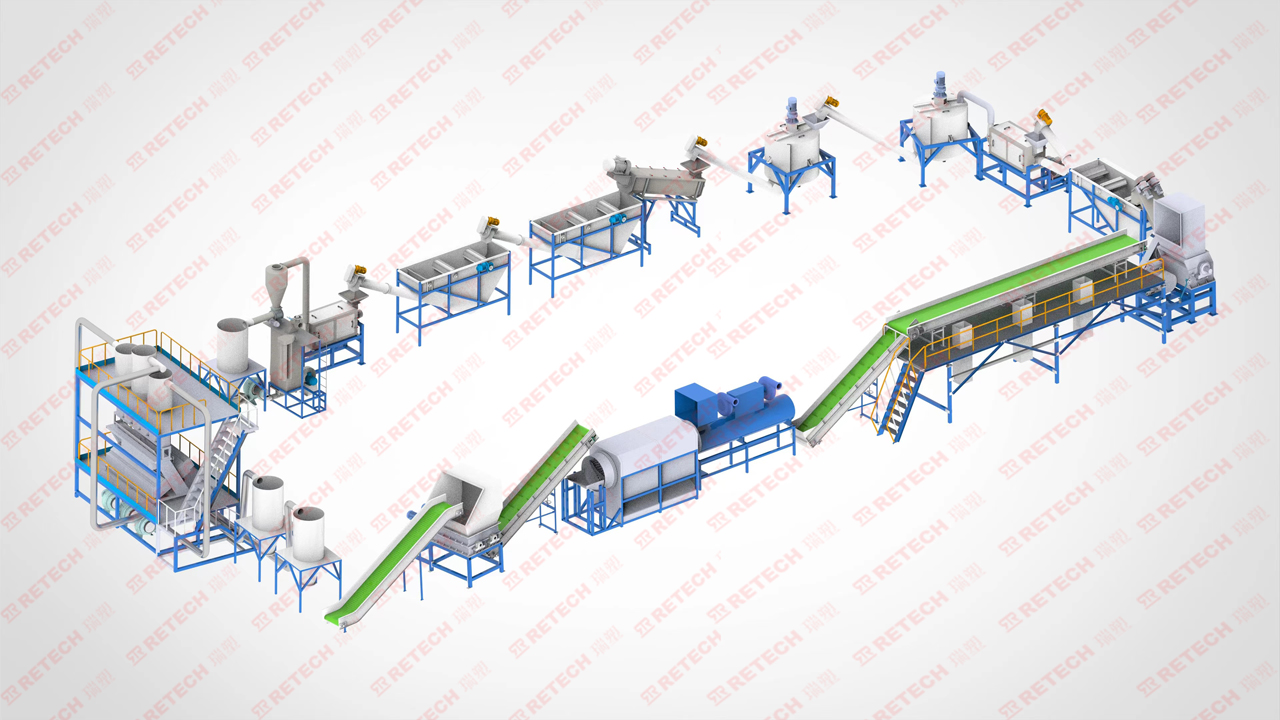

Plastic 2000kg/hr PET Bottle Flakes Crushing Washing Recycling Machine Plant

1. Project introduction of PET bottle recycling machine:

(1) This PET bottle washing line is specially design to deal with, PET bottles, such mineral water bottle, beverage bottles... the main function of this line usually include four points. First to crush and wash the PET flakes finally get clean flakes. Second to remove the labels thoroughly, third to remove the bottles caps fourth to dry the PET flakes, finally to get clean, pure and dry PET flakes. Combining wet crusher, friction washer, high speed friction washer floating washer and hot washer to guarantee the finally flakes good quality. And this production line is with high automatically operation and labor savings quality. With advanced design concept and constantly advises from customers, we can customized to meet all your specially demands.

(2) This PET bottle crushing washing recycling line could be installed "I", "L", and "U" shapes according to your workshop. We also could help you to design how to install the machines in your factory.

2. Project information of PET bottle recycling machine:

(1) Space: about 63m* 3.5m* 5m (L*W*H) - I type

(2) Electric Grid standard: according to customer's working location

(3) Water consumption: 4~5Ton/hour

(4) Installed power: 180kw, real power consumption is about 120kw/h

(5) Labors: 6-8 workers/shift

(6) Cables: offered by customer

3. Final PET flakes condition of PET bottle recycling machine:

Intrinsic Viscosity | Intrinsic Viscosity 0.71 ~ 0.78 dl/g depend on bottles I. V. |

Bulk density (min. /avg. /max. ) | 400/500/600 kg/m 3 |

Flake Size Mainly 8~12mm Size ≤ 1 mm Size ≥ 14 mm | could be customized ≥95 % < 2 % < 3 % |

Humidity | ≤ 1.5 % |

PE, PP | ≤ 20 ppm |

Paper | ≤ 20 ppm |

Glues/Hot melts | ≤ 20 ppm |

Organics | ≤ 20 ppm |

Metals | ≤ 20 ppm |

In-organics | ≤ 20 ppm |

PVC | ≤ 20 ppm |

Total impurity | ≤ 200 ppm |

Final PET flakes could be fiber grade |

4.Equipment list of PET bottle recycling machine:

No. | Name | Qty | Remarks |

1 | Belt conveyer | 1 |

|

2 | Mechanical Label Separator | 1 |

|

3 | Manual Sorting | 1 |

|

4 | Metal detector | 1 |

|

5 | Belt conveyer | 1 |

|

6 | Wet Crusher | 1 |

|

7 | Screw Conveyer | 1 |

|

8 | Floating washer | 1 |

|

9 | High speed friction washer | 1 |

|

10 | Screw conveyer | 1 |

|

11 | Hot Washer | 1 |

|

12 | Screw Conveyer | 1 |

|

13 | High speed friction washer | 1 |

|

14 | Floating washer | 1 |

|

15 | Screw Conveyer | 1 |

|

16 | Floating washer | 1 |

|

17 | Screw conveyer | 1 |

|

18 | Horizontal Dewatering Machine | 1 |

|

19 | Zigzag Separator | 1 |

|

20 | Storage Hopper | 1 |

|

21 | Electric Elements | 1 |

|

5.Detail part of PET bottle recycling machine: